Compression mould usually use hydraulic press machine and the cavity and core is fixed to top and bottom platens of machine. Once the material is placed into the open mould, the machine closes, mould get heated, then the press pressure force material to flow all over the mould.

In above process, the material which placed into open mould are normally SMC, BMC,GMT etc compound material. So we always refer this type of comperssion mould to SMC mould, BMC mould, GMT mould.

There are certian difference between SMC, BMC and GMT material.

SMC(sheet molding compounds) is a fiber reinforced thermoset material often used for large parts where highr strength is needed.

BMC (Bulk molding compounds)

BMC (Bulk molding compounds) are characterised by its doughy texture and short fiber.

GMT(Glass matreinforced thermoplastic)

GMT(Glass matreinforced thermoplastic) can also be recycled.

Only GMT material need to be preheated.

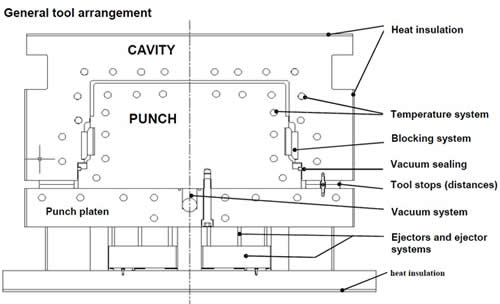

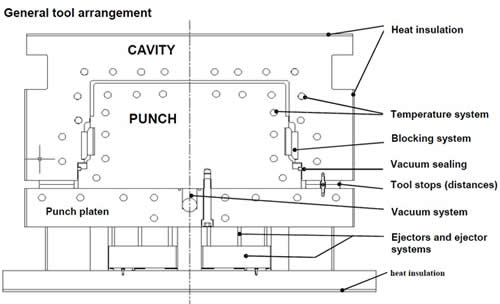

Instead of cooling channel in injection mould, SMC mould require a heating channel. Normal heating systems are steam, oil, electricity or high perssure water.

The working temperature of the SMC mould is usually 140 degree to 160 degree. When designing the termprature system it is essential to be abe to keep the surface of the mould within close temprature. A mould with uniform temperature will fill easier and produce parts with less warpage, imprived dimensional stability and a uniform surface appearance.